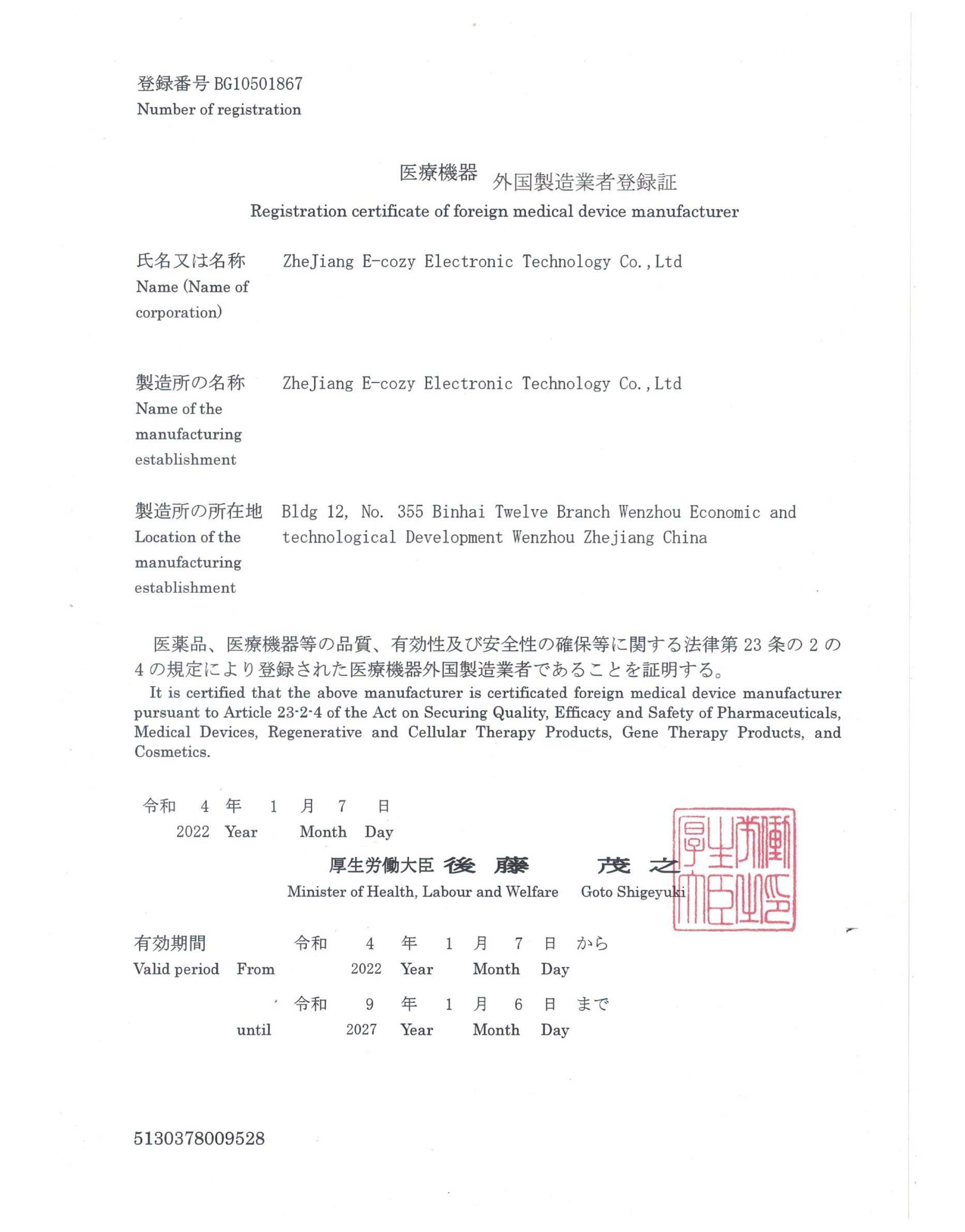

Certified Excellence: Global Recognition

ISO 9001

This certification signifies our adherence to a globally recognized standard for quality management systems. It ensures that we consistently provide products and services that meet customer and regulatory requirements.

ISO 14001

Demonstrating our commitment to environmental responsibility, ISO 14001 certifies our effective environmental management system, ensuring sustainable practices throughout our operations.

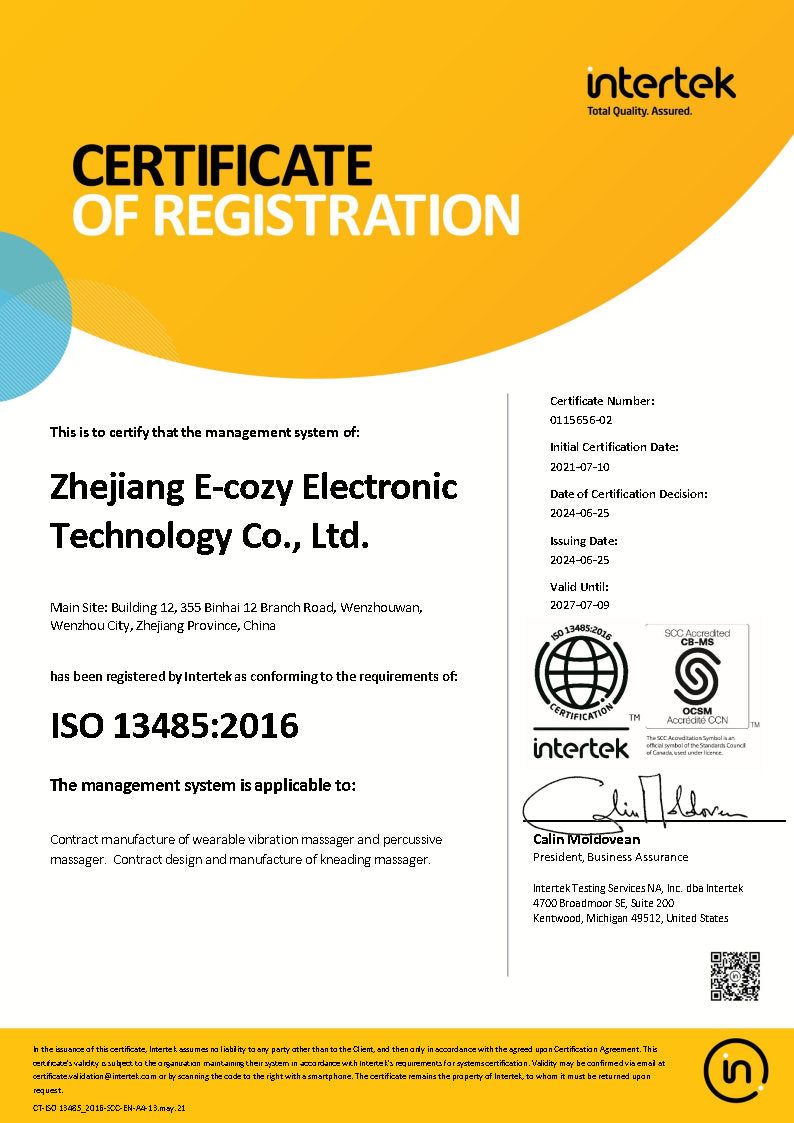

ISO 13485

Specifically for medical devices, this certification highlights our ability to provide medical devices and related services that consistently meet customer and applicable regulatory requirements.

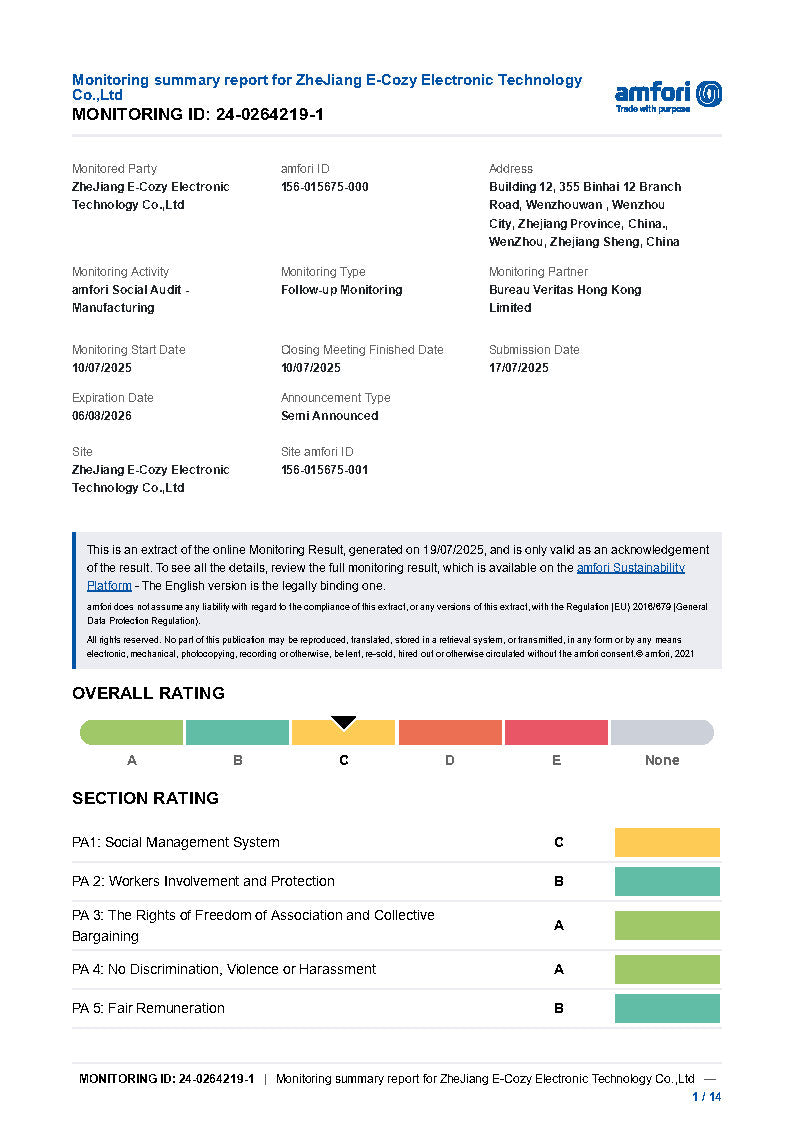

BSCI (Business Social Compliance Initiative)

Our participation in BSCI reflects our dedication to ethical business practices and social compliance in our supply chain, ensuring fair labor practices and safe working conditions.

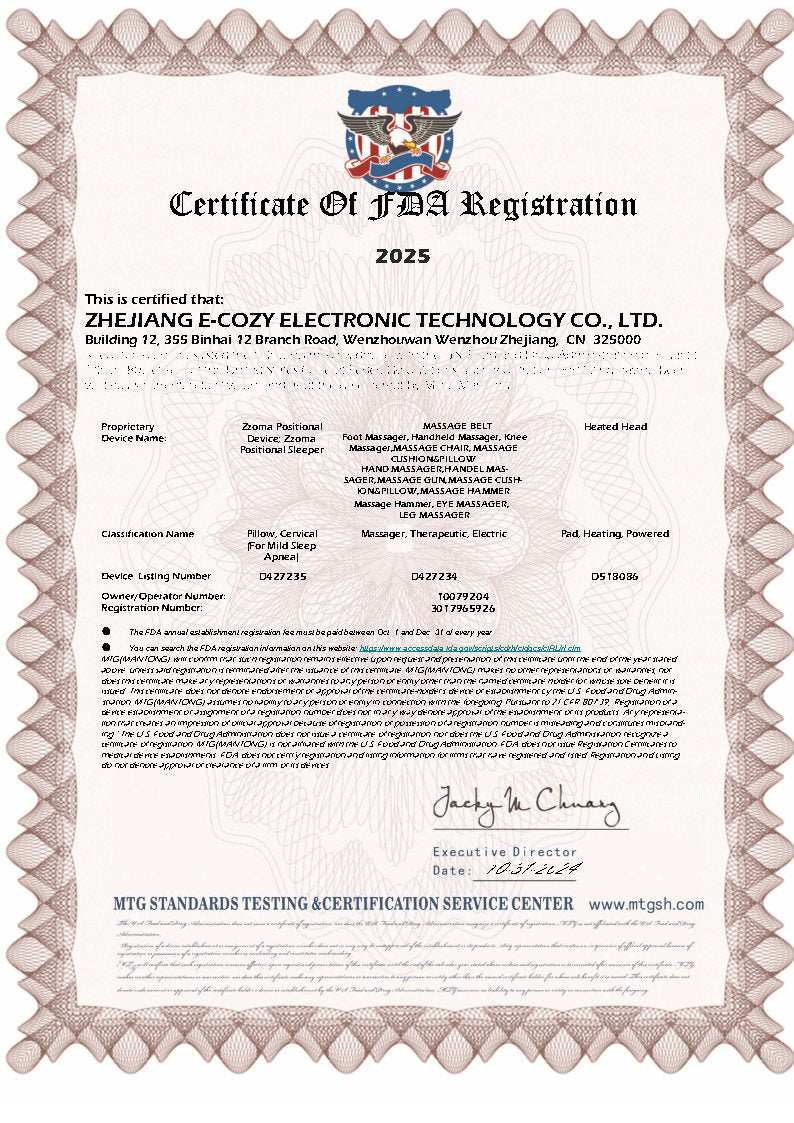

FDA (Food and Drug Administration)

Our products comply with FDA regulations, particularly for devices intended for health and wellness applications in the US market.

FCC (Federal Communications Commission)

This certification ensures that our electronic products meet the standards for electromagnetic interference, making them safe for use in the US.

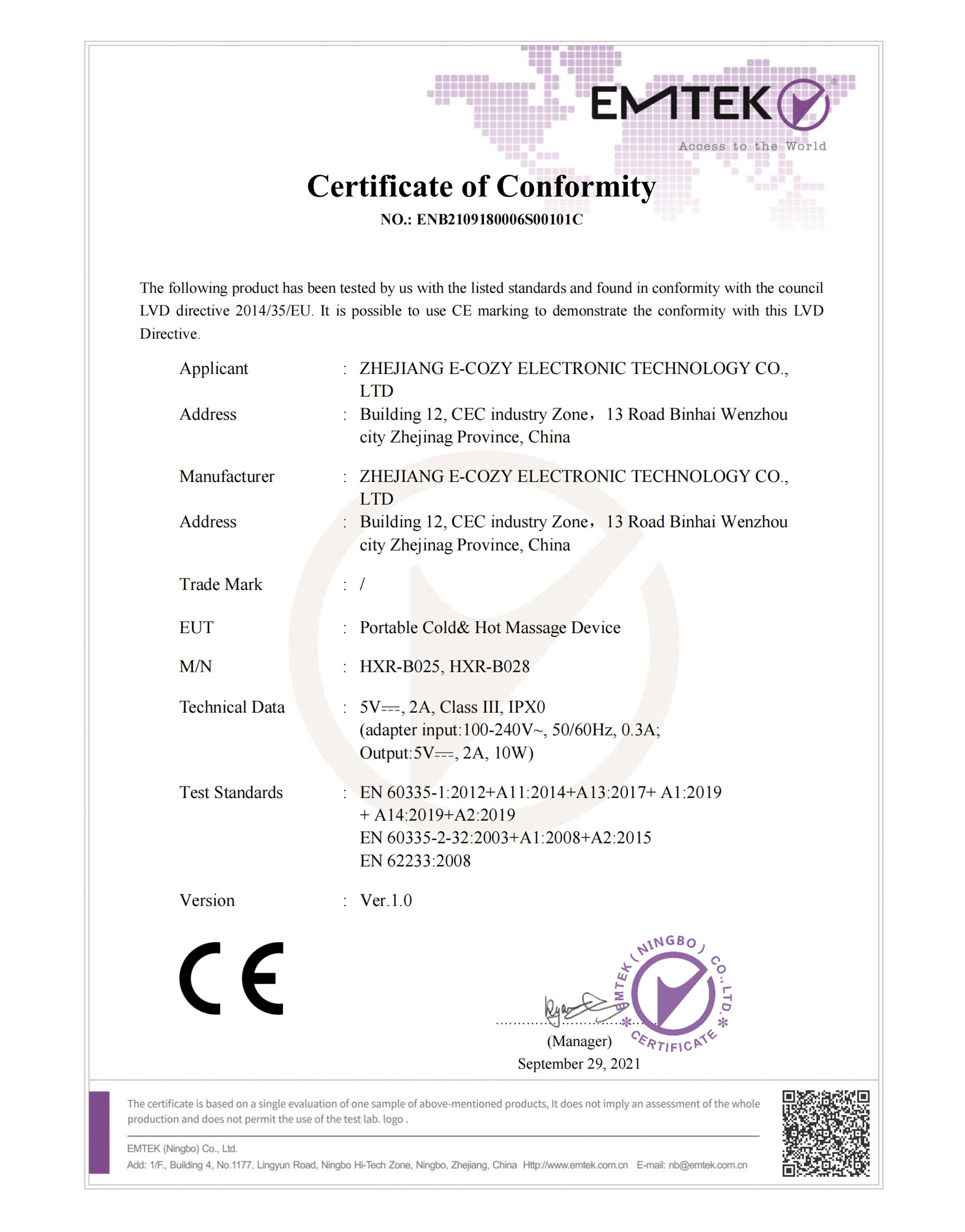

CE (Conformité Européenne)

The CE mark indicates that our products comply with European Union health, safety, and environmental protection legislation, allowing free movement within the European market.

RoHS (Restriction of Hazardous Substances)

This directive restricts the use of specific hazardous materials in electrical and electronic products, underscoring our commitment to environmental safety and consumer health.

UKCA (UK Conformity Assessed)

As the UK's product marking for goods placed on the market in Great Britain, UKCA ensures our products meet the necessary safety and quality standards for the UK market, including UKCA-LVD (Low Voltage Directive) and UKCA-EMC (Electromagnetic Compatibility).

Our commitment to quality is validated by a range of internationally recognized certifications.

Our 6-Step Quality Assurance Process

-

STEP 1

STEP 1Incoming Material Inspection (IQC)

Before production begins, all raw materials and components undergo thorough inspection to verify their quality, compliance, and adherence to our strict specifications. This includes checks on dimensions, appearance, physical & chemical properties, and specialized tests like microresistance and power-on tests.

-

STEP 2

STEP 2In-Process Quality Control (IPQC)

Throughout the manufacturing process, our quality control team conducts real-time monitoring and inspections. This proactive approach allows us to identify and address any potential issues immediately, preventing defects from propagating.

-

STEP 3

STEP 3Assembly Line Online QC Inspection

At various stages of the assembly line, dedicated quality control checks are performed to ensure components are correctly assembled and initial functionalities are working as intended.

-

STEP 4

STEP 4Packaging Line FQC Inspection (Final Quality Control)

Before products are packaged, a comprehensive final quality check is conducted. This includes verifying product appearance, functionality, and ensuring all accessories and packaging materials are complete and meet standards.

-

STEP 5

STEP 5Internal OQC Inspection (Outgoing Quality Control)

A final sampling inspection is performed on finished goods before they are moved to the warehouse. This ensures that batch quality is consistent and meets our internal and international quality benchmarks.

-

STEP 6

STEP 6Customer OQC Inspection (Optional)

For our B2B partners, we offer the option for pre-shipment inspection by your representatives or a third-party agency, ensuring complete transparency and satisfaction before dispatch.

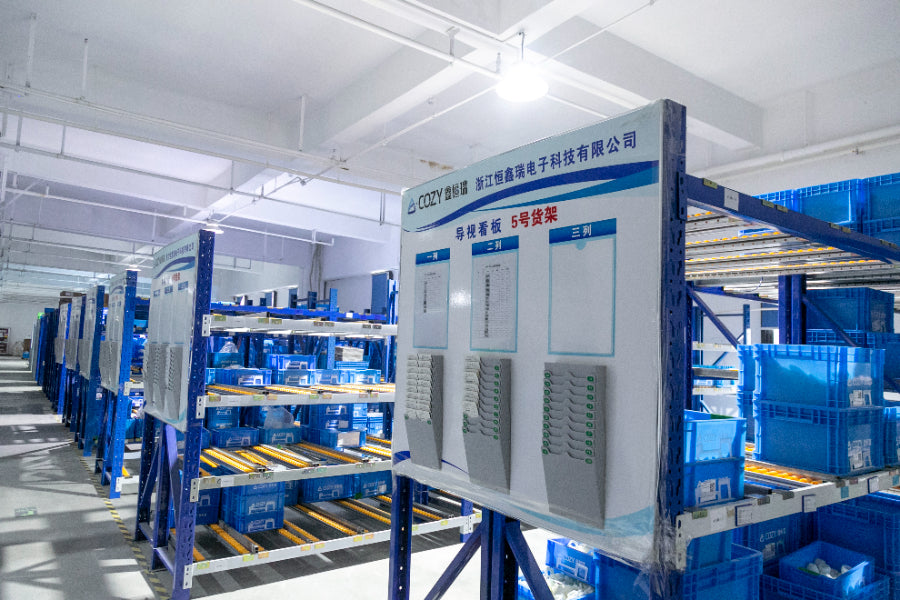

Rigorous Quality Control: From Concept to Customer

Our dedication to quality is embedded in every stage of our production process. We implement a comprehensive, multi-layered quality control system to ensure the durability, safety, and performance of every Ecozy Global product. From the moment raw materials arrive to the final product shipment, we conduct rigorous testing and inspections.